COTTON/POLYESTER COTTON CONVEYOR BELTS

Bullflex Rubbers’ Cotton/Polyester Cotton Conveyor Belts are known for their durability, reliability and versatility. Made from a blend of cotton and polyester fibers, they offer high abrasion and impact resistance, as well as excellent tensile strength. These belts are lightweight, flexible and resistant to moisture, making them ideal for use in various industries. Their low elongation, resistance to shrinkage and stretching also extend their lifespan. They can be customized to meet specific needs with surface patterns, cover materials and edge profiles. In summary, cotton/polyester cotton conveyor belts offer a cost-effective solution for many industrial applications.

Product Application:

Bullflex Rubbers’ Cotton/Polyester Cotton Conveyor Belts are widely used in various industries due to their durability, flexibility, and excellent mechanical properties. They are used in the textile industry for transporting raw materials and finished goods, in the food industry for transporting food items while complying with FDA regulations, and in the packaging industry for labeling, canning, bottling, and filling machines. The mining industry uses them for transporting heavy loads of raw materials from mines to processing plants, while the agriculture industry uses them for transporting crops from farms to storage facilities. In sawmills and woodworking plants, they are used for transporting wood chips and sawdust. Additionally, these belts are used in recycling plants for transporting recyclable materials, and in the automotive industry for transporting parts and components during the production process. Their durability, strength, cost-effectiveness and flexibility make them a versatile and suitable choice for a wide range of industries and applications.

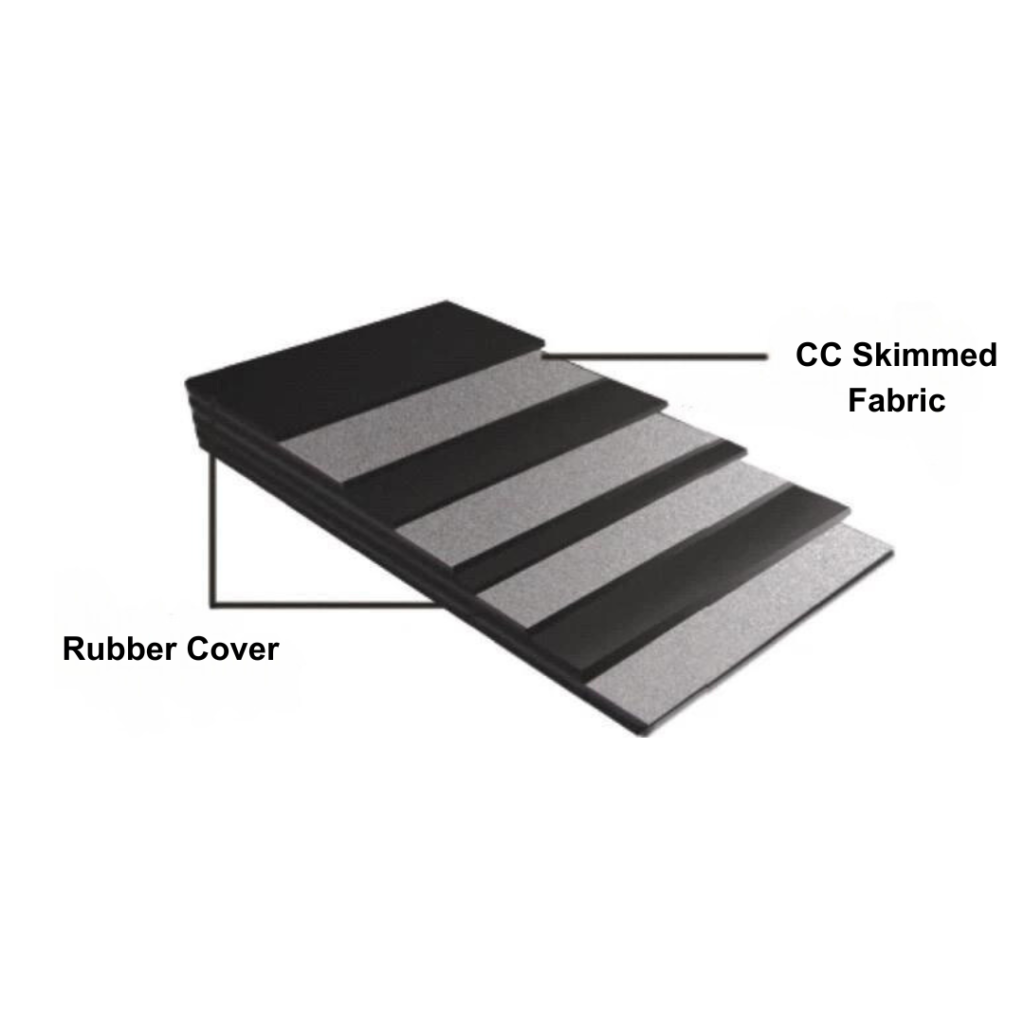

Product Characteristics:

| Common Widths : | 50 mm to 2600 mm |

| Carcass Variety Available : | EP / NN / EE / CC |

| Common Belt Rating : | 200 to 3150 kN/m |

| No. of Plies : | 1 ply to 7 ply |

| Rubber Cover Compounds : | Refer table for detailed properties |

| Rubber Cover Thickness : | 0.5 mm to 25 mm |

| Edge : | Cut/Moulded Edge |

| Splicing Method : | Hot/ Cold/ Mechanical |

| Belt Labelling : | Assigning distinct Product identification (Brand Name) to the product at every 6 meters. |