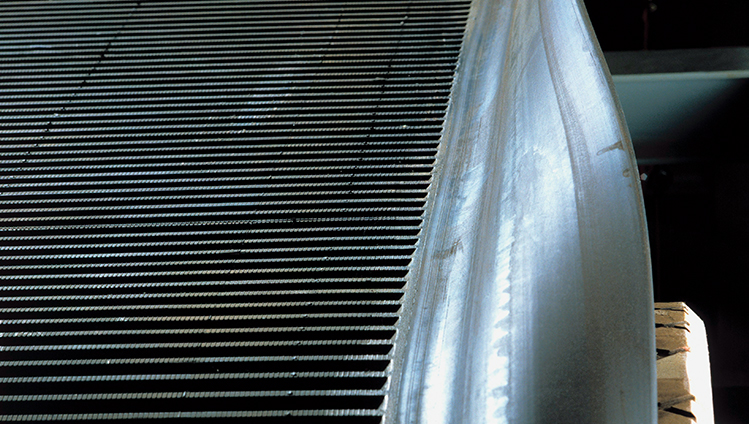

Filtration conveyor BELTS

Bullflex Rubbers’ Filtration Conveyor Belts are expertly designed conveyor belts that are engineered to filter and separate solid particles from liquids or gases. These belts are made from high-quality synthetic materials that offer excellent resistance to heat, chemicals, and abrasion. Bullflex Rubbers’ Filtration Conveyor Belts are an essential component in various industrial processes where separating solid particles from liquids or gases is crucial. These specialized conveyor belts offer a reliable and efficient solution to industries that require filtration and separation in their production processes.

Product Application:

Filtration Conveyor Belts are essential in industries where separating solids and liquids or gases is necessary. Bullflex Rubbers’ Filtration Conveyor Belts are widely used in various applications, including wastewater treatment, food processing, chemical industry, mining industry, and oil and gas industry. These belts are designed with synthetic materials that are highly resistant to chemicals, heat, and abrasion, making them durable and reliable in harsh conditions.

In wastewater treatment plants, Filtration Conveyor Belts are an integral part of the filtration process, separating solid waste from water. In the food processing industry, they are used to produce beverages, dairy products, and other food items, where the separation of solids and liquids is necessary. In the chemical industry, Filtration Conveyor Belts are used in the production of chemicals, pharmaceuticals, and other industrial applications. In the mining industry, they are used to extract minerals from ore and filter out solid waste from water. In the oil and gas industry, they are used to separate oil and water, remove impurities from oil and gas, and in oil refineries and drilling operations.

Product Characteristics:

| Common Widths : | 50 mm to 2600 mm |

| Carcass Variety Available : | EP / NN / EE / CC |

| Common Belt Rating : | 200 to 3150 kN/m |

| No. of Plies : | 1 ply to 7 ply |

| Rubber Cover Compounds : | Refer table for detailed properties |

| Rubber Cover Thickness : | 0.5 mm to 25 mm |

| Edge : | Cut/Moulded Edge |

| Splicing Method : | Hot/ Cold/ Mechanical |

| Belt Labelling : | Assigning distinct Product identification (Brand Name) to the product at every 6 meters. |